Reinforcement cages are a familiar sight on construction sites. But despite their routine appearance, these structures can present significant safety risks before concrete is poured — especially when their temporary nature is overlooked.

At Amrose Associates, we believe that rebar stability during the construction phase deserves far greater scrutiny. Serious incidents involving cage collapses have occurred across the UK, sometimes resulting in injury or worse. These are not just unfortunate accidents — they’re often the result of avoidable failures in planning, coordination and temporary works design.

A Critical but Overlooked Risk

Reinforcement bars (rebar) are used to give concrete the tensile strength it naturally lacks. Cages made from rebar are often tall, slender structures, fabricated on or off site and then positioned before concrete placement. Until the concrete is poured and cured, these cages remain in a vulnerable, non-structural state.

Factors such as wind, live loads from operatives and equipment, accidental impacts, and even small construction imperfections can all destabilise these structures. Yet, temporary stability is rarely given the same level of attention as the permanent design — an oversight that can have serious consequences.

What Makes Rebar Cages Unstable?

The reinforcement process often involves tying vertical and horizontal bars together with wire — this offers positioning support but not structural strength. Taller cages, thinner bars, and more sustainable designs have become the norm, but they’re also more prone to buckling and instability.

Our engineering team considers a wide range of risks when designing or assessing rebar cages, including:

- Wind loads acting on both sides of a cage

- Live loads from workers, tools, and materials

- Accidental impacts during lifting or formwork installation

- Notional loads and imperfections due to cages not being perfectly plumb

Each of these requires careful calculation and appropriate mitigation, whether through added stability features or improved site methodology.

Common Failure Modes — and How to Prevent Them

We’ve seen first-hand the typical ways in which reinforcement cages can fail — from scissoring caused by lapped bars, to buckling, vertical discontinuity, and racking. These failure modes are entirely preventable with the right approach.

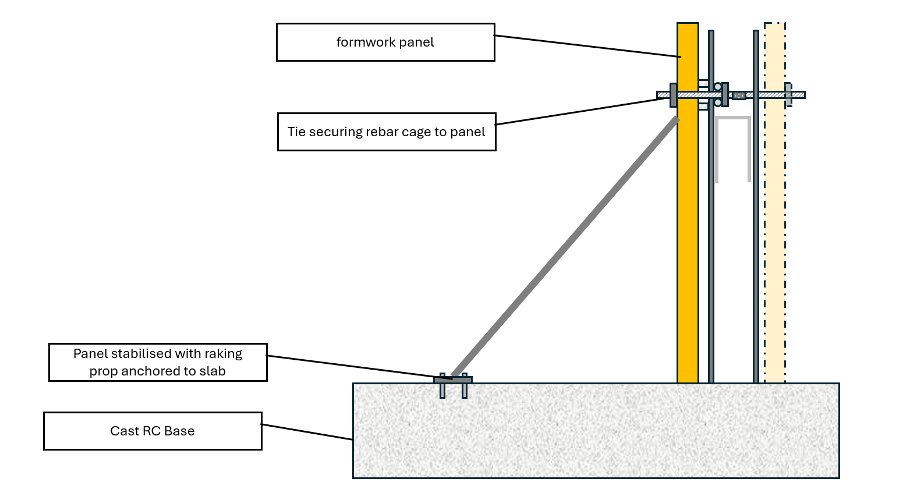

At Amrose, our team uses a mix of strategies depending on the site conditions, cage geometry, and project phase. These might include tying cages to formwork, using raking props, adding bracing bars, incorporating sacrificial steelwork, or designing scaffold supports that double as stability frames.

All of our designs follow guidance from the Temporary Works Forum (TWf2021:01), ensuring compliance with current best practice and standards.

Why It Matters

Temporary works are a vital part of creating safe, efficient and resilient construction environments. We work with contractors and design teams to make sure these risks are addressed early and thoroughly, minimising the chance of project delays or site incidents.

If you’re working on a project involving large or complex rebar cages, it’s never too early to bring in specialist advice.

Contact us if you’d like to work with our expert engineers.