What are 3D cloud scans and what role do they play in complex structural design?

A 3D point cloud scan plays a significant role in engineering design by providing a highly accurate digital representation of physical objects or environments.

They improve accuracy, aid visualisation and generate detailed data to support some of our most complex engineering design work.

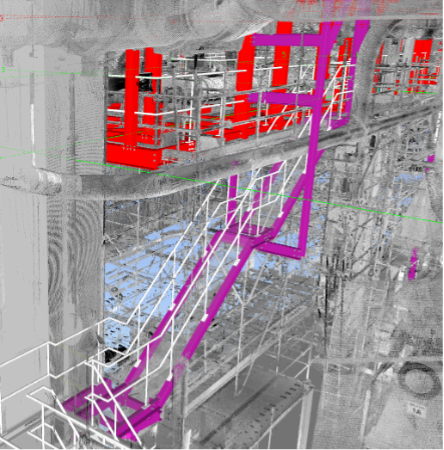

We recently utilised 3D cloud scans during a complex industrial steel structural design for Drax Power Station, where we were engineering a solution that needed to integrate with an existing historic structure.

These are the key reasons why 3D point cloud scanning is such an integral element of complex structural design, particularly in industrial settings where new engineering is being designed on a site which may be heavily congested with historic structures and plant:

- Accurate Data Capture: 3D point clouds are generated by laser scanning or photogrammetry techniques and consist of millions (or even billions) of data points. Each point represents a specific location on the surface of an object or environment. This high level of detail ensures that all the features of the physical object or space are captured accurately.

- Reverse Engineering: For existing structures or components, a 3D point cloud scan can be used to reverse engineer the design. It allows our engineers to create digital models of complex shapes or objects that might not have original CAD files available, especially when working with older structures or parts.

- Design Visualisation: Our engineers can import the point cloud data into CAD or BIM software to create detailed 3D models. This helps them visualise the design in a real-world context, making it easier to spot design flaws, optimise the design, and better communicate the concept to stakeholders.

- Measurement and Analysis: 3D point clouds enable precise measurements of distances, angles, and volumes. Our engineers can perform detailed analysis on the scanned data to assess the condition, dimensions, or alignment of physical objects. It’s especially helpful for detecting deviations from the intended design or verifying the accuracy of installations.

- Integration with CAD Models: Our engineers can combine point cloud data with existing CAD models, allowing them to compare and integrate new designs with real-world conditions. This is particularly useful for renovations, expansions, or upgrades to existing infrastructure, where the new design needs to fit seamlessly into the existing environment.

- Documentation and Record-Keeping: A 3D point cloud scan provides a permanent, detailed record of the as-built state of a structure or environment. This can be essential for future maintenance, repairs, or any further design work. It ensures that our engineers have a reliable baseline to work from.

- Efficiency and Reduced Errors: By providing a detailed and accurate starting point for design, point cloud scans reduce the likelihood of errors that could arise from relying on manual measurements or outdated blueprints. They streamline workflows, reduce the time spent on site visits, and improve the overall efficiency of the design process.

3D point cloud scans improve the precision, efficiency, and effectiveness of the engineering design process, whether for new constructions, renovations, reverse engineering, or any project requiring detailed physical data. Our tailored approach means that, depending on the project and brief, we draw on data-driven tools such as this to ensure safety, performance, and reliability. Our knowledge and experience in advanced analysis, fabrication, and detailing allows us to tackle even the most demanding industrial projects.

If you would like to discuss a complex engineering project with our specialist engineers contact us on 0113 418 0694.