In partnership with Falcon Tower Crane Services, we recently developed and improved an innovative in-core climbing tower crane tie design, solving real practical challenges, improving safety and creating a solution ready for future projects.

The Challenge

Real-world engineering and design development is about collaboration, iteration and (sometimes) physically testing concepts to prove performance prior to implementation at site.

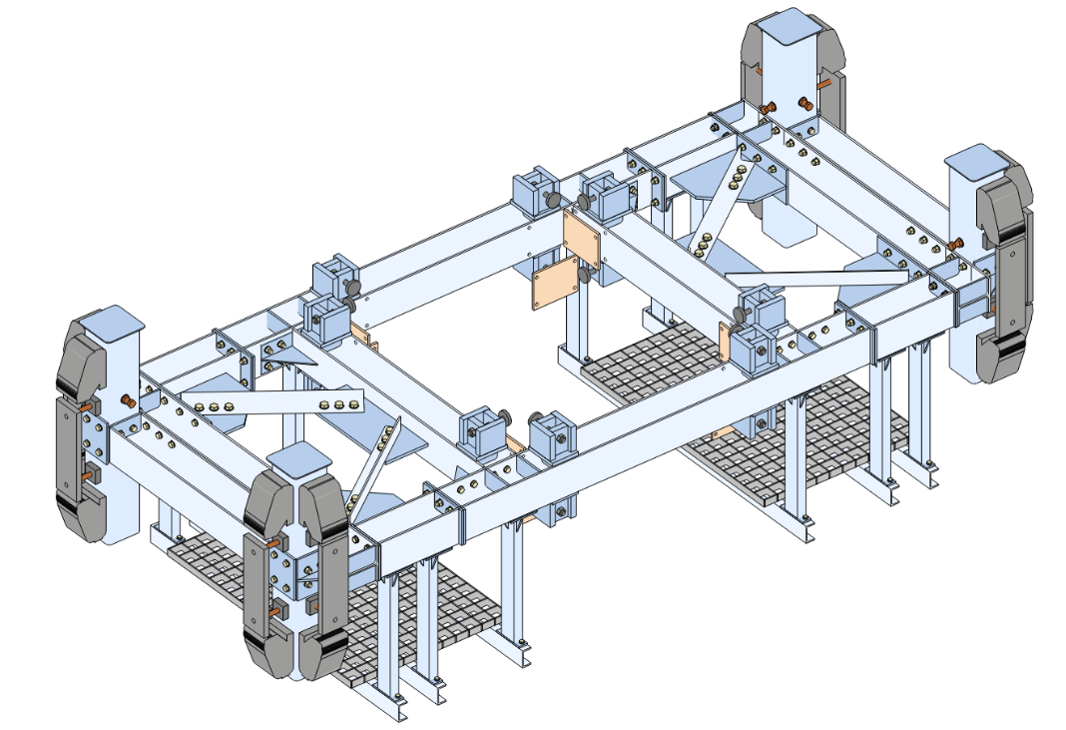

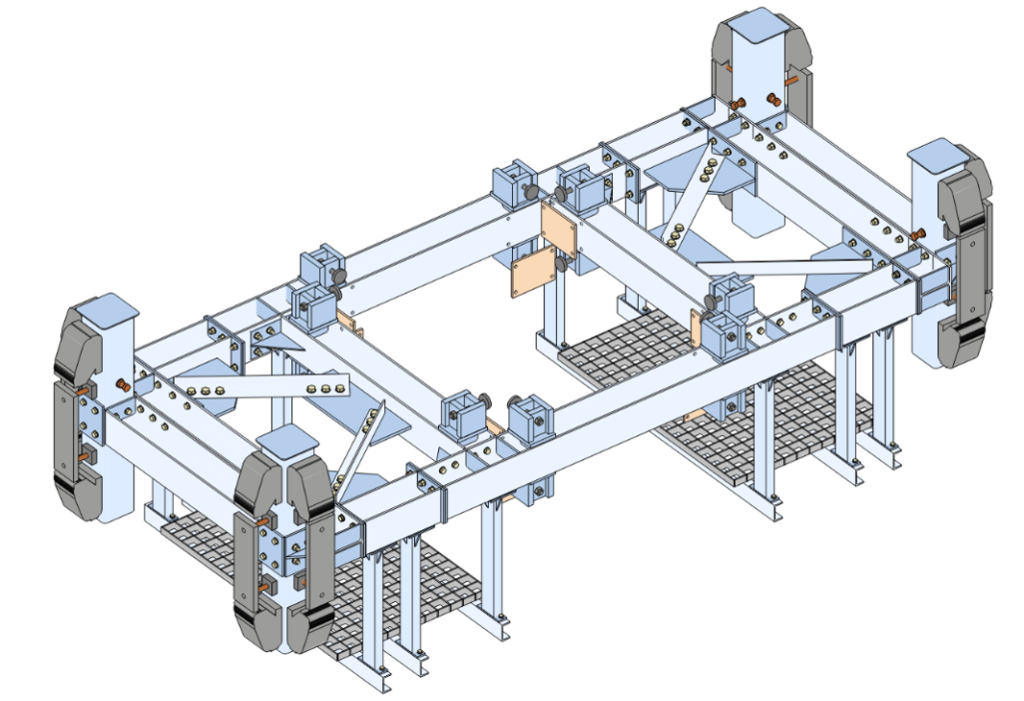

Tower crane ties are critical for providing stability to cranes during high-rise construction. We worked in collaboration with Falcon Tower Crane Services to develop an “in-core” climbing arrangement that could withstand the dynamic loads of crane operation.

The original design adopted a proprietary roller system with bespoke skid plates and adjustable threaded studs. However, during installation, issues arose when several skid plates were not adjusted fully against the core wall face. As the crane mast naturally deflected horizontally during installation of the components, unintended lateral loads were transferred into the studs, causing permanent damage and deformation (without compromising safety). This led to tricky operation to repair the equipment whilst in the tight core space.

Our Approach

Rather than applying a “quick fix,” Amrose worked closely with Falcon to review the issues and explore improved solutions through a collaborative design development process.

Key stages included:

- Analysis of site performance: Reviewing why the original skid plates underperformed and identifying the root causes.

- Option development: Considering alternatives such as wedge jacks and modified roller arrangements.

- Practical testing: Conducting physical mock-ups to validate the feasibility of potential solutions.

- Iterative refinement: Combining engineering analysis with site feedback to shape the design.

Adopting lessons learned from the earlier work led to proprietary Titan ‘wedge’ jacks being explored alongside a bespoke roller arrangement. On paper, they offered a neat solution but mock-up testing quickly revealed they couldn’t be used horizontally to carry vertical loads. This evolved further into a design with a rotating retainer housing, securing the nut in place while still allowing the threaded stud to rotate. Two phases of mock-up testing validated the approach before implementation.

The Outcome

Through close collaboration, openness to testing and iterative development, Amrose and Falcon developed an alternative that:

- Eliminated the installation challenges experienced in the initial design.

- Enhanced both safety and reliability of the crane tie system.

- Created a robust, repeatable solution that can be adopted for future projects.

Why It Matters

This project is a prime example of how Amrose combines technical rigour with practical constructability, working side by side with partners on site to overcome challenges. By blending engineering expertise with hands-on testing, we delivered a better outcome for Falcon and established a design ready for future use across multiple projects.

If you’d like to know more about our design development process, Ask Amrose. Call 0113 418 0694 or email enquiries@amroseassociates.com